News

Bridging the Gap in Vertical Machining Center Performance

There’s a new machine tool coming down the road that is going to make a lot of people in the machining industry very happy. It’s a top of the pyramid vertical machining center with enough performance to delight machinists from job shops to die mold and everything in between. Drum

SVM 4100: This One’s for the Machinists with a Dream

The new SVM 4100 goes toe-to-toe with the best value vertical machining centers.

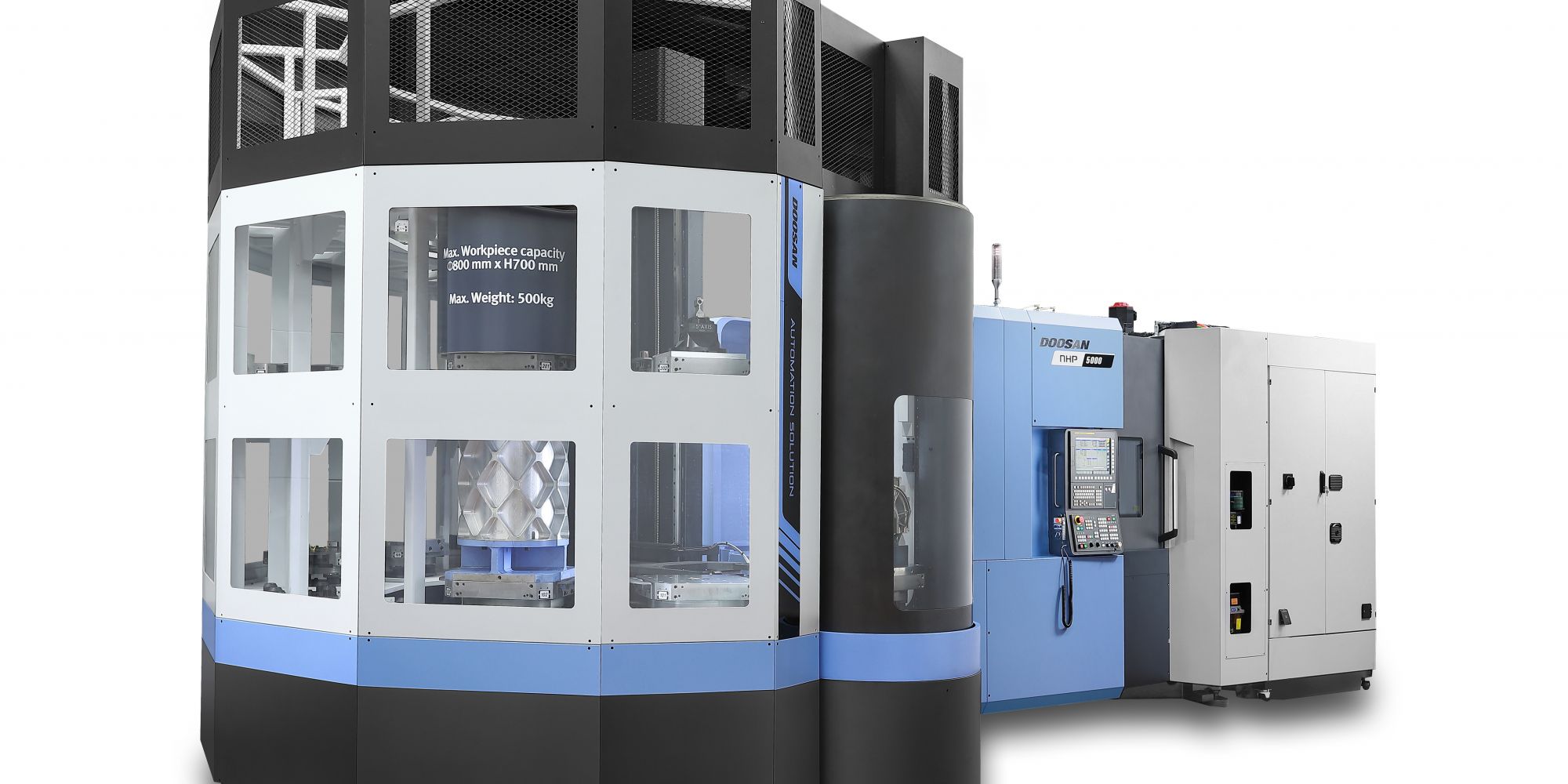

Multiply Machining Center Throughput with a Pallet System

Machine shops have reached a turning point (no pun intended) when it comes to automation. The move forward is driven by the need to produce precision parts faster while simultaneously facing a skilled labor shortage. Bar feeders and robots on turning centers are common examples of automation and have been

The Doosan DVF Series: Complex 5-Axis Machining Made Easy

As we’ve mentioned before, our customers are an integral part of our engineering efforts to continually improve our products. Their feedback and suggestions enable us to bring new products to market and continually fine-tune them to keep up with changing demands in the market place. A perfect example is the

Need a Spare? Explore Doosan’s 6-Month Supply of Parts

It may be hard to believe, but even super-tough Doosan machines need a little TLC once in a while. Over time, parts wear out and need to be replaced. That’s just a fact of shop life. Hopefully, you’ll discover any imminent failure during a routine Preventive Maintenance check, but even

New Machine Tool Workforce Development Alliance

FANUC America and Doosan Machine Tools America form partnership to better prepare future operators. Rochester Hills, MI – (April 15, 2021) – FANUC America, a leading factory automation solutions provider, and Doosan Machine Tools America, a leading provider of CNC machine tools, are working together to build the next generation

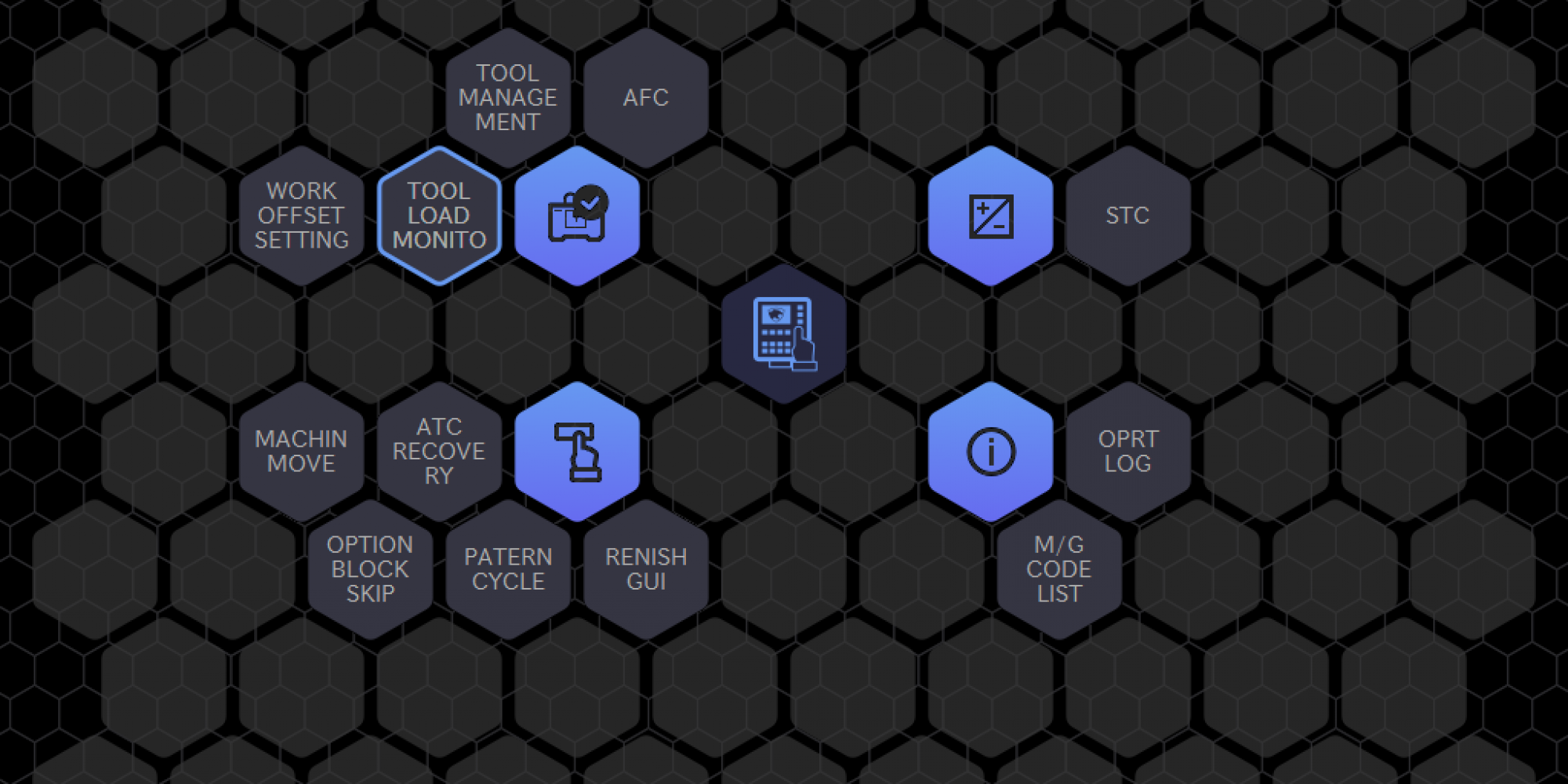

The Control Game Changer: The FANUC 0iF Plus with Touchscreen and iHMI

The standard FANUC 0i-F has been the industry go-to CNC control for decades. There’s a good reason for that: it’s reliable and it gets the job done. But with a whole new generation of operators entering the manufacturing workforce, it made sense to give them an interface that is as

Perform Preventive Maintenance on the Fly and Minimize Downtime

The easiest way to avoid missed delivery dates and costly CNC machine repairs is to perform Preventive Maintenance (PM) on a regular basis. “Up to 40% of the repair work that I see could have been prevented by PM,” said Darryl Hardt, Assistant Manager of Service Training for Doosan Machine

Meet Horsepower Inc: 2020 #PartPride Grand Prize Winner

HPi is also an unabashed Doosan Shop, with nine active models currently on the floor. In the summer of 2020, the company entered #PartPride, our social media part-making competition. The work was good enough to take the 2020 grand prize, besting nine other monthly winners to take the top prize